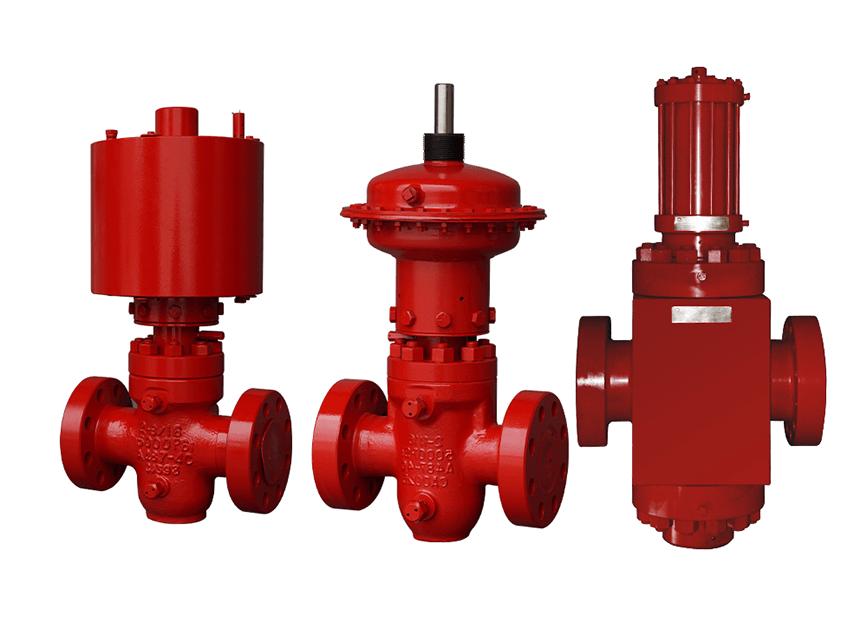

Diaphragm and Piston Pneumatic Actuators

API 6A Pneumatic Piston & Diaphragm Actuators

As a dedicated pneumatic actuator valve manufacturer, Tiger Valve employs a staff that works hard to develop state-of-the-art diaphragm and piston actuators. Tiger Valve currently provides pneumatic diaphragm actuators and pneumatic piston actuators to the United States and Canada. Featuring back seat verification, fire safety seat and more, our actuators are highly safe when used correctly. They’re designed to open and close gate valves properly when needed.

When you order your pneumatic diaphragm actuator and pneumatic piston actuator valves from Tiger Valve, you’ll receive a quality engineered product and exceptional customer service. We take pride in providing pneumatic operated valves that our customers can count on.

Introduction and Operation

Indicator

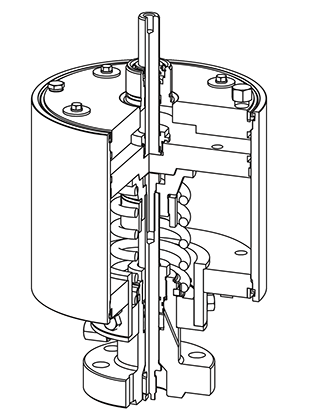

The TVC Piston Type Pneumatic Actuator is used to open and close a gate valve. The gate valve can be reverse acting or direct acting. The actuator is a fail safe design. A coil spring is incorporated to assist in elevating the gate when there is no line pressure. In a reverse acting gate valve mode, the fail safe action of the bonnet stem insures closing on loss of control supply pressure. In a direct acting gate valve mode, with loss of control supply pressure, the fail safe actuator will open the gate valve.

The design of the actuator is rugged, easy to adapt to a bonnet and easy to maintain. This Piston Actuator can be used on or offshore. Normal operation would be as a secondary master or wing valve.

The maximum control pressure of the Actuator is 170 PSI (12 bar). The test pressure is 255 PSI (18 bar). This Actuator is designed to adapt to any “like design” gate valve in the industry.

Operation

The TVC Piston Type Pneumatic Actuator is operated by an air or gas pressure supply to the top port of the actuator head. This gas pressure will act on the area of the piston forcing the bonnet stem down to either open or close the gate valve depending on the gate design.

In a reverse acting gate valve, having a pressure differential across the gate, the initial opening might exhibit a quick response as the pressure differential is reduced. This does not cause damage or hinder valve function.

When control supply pressure is reduced the closing motion will be smooth without any hesitation. This action can best be described as a fail close for reverse acting gates and fail open for direct acting gates. As a rule of motion, the larger the exhaust port in the actuator, the quicker the actuator will close.

Features and Benefits

• Improved Sealing Technology:

Longer seal life for bonnet and top shaft using Poly Pak seals.

• Personnel Safety:

A safety shear ring prevents actuator removal when unknown control pressure is trapped. This guards against personnel injury.

• Control Pressure Protection:

A Pressure relief device on the top of piston housing protects personnel from over-pressurization of the actuator. It is designed for easy field inspection and replacement.

• Corrosion Resistance:

Non stainless components are coated with phosphate for longer wear life.

• No Special Tools required:

No special tools are required for spring installation or removal.

• Back Seat Verification:

A test fitting located above bonnet stem backseat provides verification of the stem to bonnet, metal to metal seal integrity.

• Fire safe seal:

A metal to metal seat design between actuator, bonnet and stem serves as a secondary fireseal if high temperatures destroy lower stem bonnet packing.

• Heavy Duty Compression Spring:

The spring provides extra force in the fail close operation and secures positive backseat engagement when flow line is at low pressure.

• Indicator Rod or Top Shaft:

Shows the position of the gate. Made from stainless steel, it requires no protection from the elements.

Parts and Specifications

Control Pressure Equations

View EquationsActuator Sizes, Dimensions, Weight and Volume

Diaphragm Pneumatic Actuator

Introduction and Operation

Introduction

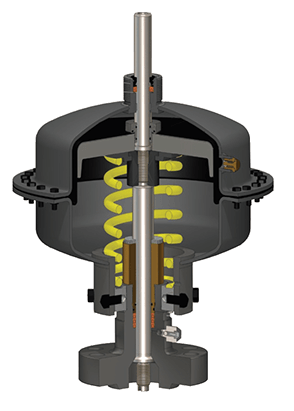

The actuator design is simple in concept. The operating principle and fewer components make this actuator long lasting and trouble free. It is rugged, easily adaptable, light weight, and easy to maintain.

Our Diaphragm Pneumatic Actuator can be used on land or offshore installations. This actuator delivers reliable fail safe performance. It is ideally suited for wellhead secondary master valves, wing valves, on flow lines, header valves, gathering lines and for casing relief valves. The maximum control pressure is 170psi (12 bar). A heavy duty spring insures complete valve stroke closure when gate valve pressure is at 0 psi.

Our Diaphragm Pneumatic Actuator can be prepared as a complete assembly with gate valve or as an actuated bonnet assembly.

The actuator is designed to operate any of the industry manufacturer’s gate valves. It is sized to provide optimal safety. The utilization of materials, seals and coating application will provide years of service in the harshest environmental conditions

Operation

The Tiger Valve Pneumatic Diaphragm Actuator is operated by applying an adequate amount of compressed air, nitrogen or gas to the side pressure port on the diaphragm head. Pneumatic pressure acting on the internal diaphragm will force the actuator downward, overcoming opposing bonnet stem and gate friction forces.

Our Diaphragm Pneumatic Actuator will open reverse or direct acting gate valves. Reverse acting gates are labeled “Fail Closed” and direct acting gate valves are labeled “Fail Open”. When actuator control pressure is removed the force/thrust upon the bonnet stem will close the gate to the “Fail Closed” position or “Fail Open” for direct acting gates.

When a reverse acting gate valve is closed with a pressure differential across the gate, the initial opening of the gate or “cracking” action will be quick and sudden. This is a normal action and does no damage to the gate valve. The function of the gate valve and actuator will not be impeded. The remainder of the stroke can be expected to be smooth and normal.

Upon loss of control supply pressure in the actuator, the closing motion should be smooth for the entire stroke. No hesitation or bumping should occur. As a rule of motion, the larger the exhaust port, the quicker the actuator will close.

It is equipped with a large helical spring. This spring is required to overcome the basic seal friction and total weight of all moving components when no valve body pressure exists.

Principles of Operation

• Improved Sealing Technology:

The diaphragm is designed with a metal sealing component. This eliminates the need to forcibly seal the diaphragm and improves design integrity.

• Personnel Safety:

A safety shear ring prevents actuator removal in the event that control pressure is unknowingly trapped.

• Less Maintenance:

Longer Seal Life is maintained through use of rolling diaphragm.

• Control Pressure Protection:

A pressure relief valve on the top diaphragm housing protects the diaphragm and personnel from over-pressurization of the actuator.

• Corrosion Resistance:

Non stainless components are phosphate coated for longer wear life.

• No Special Tools required:

No special tools are required for spring installation or removal.

• Bonnet Packing Leak Detector:

A tattletale fitting located above packing visually confirms packing leaks.

• Back Seat Verification:

A test fitting located above the bonnet stem backseat provides verification of the stem to bonnet, metal to metal seal integrity.

• Ease of Maintenance:

Top shaft seals are easily replaced in the field by simply removing a retainer ring. Disassembly of the actuator or upper housing is not required for seal replacement.

• Fire seal:

A metal to metal seat design between the actuator, bonnet and stem serves as a secondary fire seal if high temperatures destroy lower stem bonnet packing.

Parts and Specifications

Control Pressure Equations

View EquationsActuator Sizes, Dimensions, Weight and Volume

Product Line Information

Trunnion Mounted Ball Valves

© 2024

Copyright | Tiger Valve Company