Flanged Floating Ball Valves

API 6D Flanged Floating Ball Valves

As a flanged floating ball valve manufacturer, we strive to provide our American and Canadian customers with the most reliable and efficient flanged ball valves out there. Our TVC flanged floating ball valves meet all industry standards.

We’re a trusted floating ball valve manufacturer, and our team is available to answer any questions you may have. We’re dedicated to providing our clients with top-of-the-line engineered valve products and customer service. Browse the features and application standards for our two-piece bolted flanged floating ball valves below, and contact us

if you have any questions.

General Design Features

- TNACE MR0175 - (ISO 15156) (Stainless Steel ball/stem configuration)

- API 608 Compliant

- Blowout proof stem

- Forged Body on Class 900 and 1500

- Weather Seal (Class 600 and higher)

- Actuator mounting pad (4 bolt machined)

- Secondary Metal-to-Metal Sealing

- Full rated bi-directional dead-end service

- Antistatic Device

- Lockable handle

- O-Ring design (standard)

Applicable Standards

API-American Petroleum Institute

- Spec. 608 Metal Ball Valves

- Spec. 6D Specification for pipeline valves.

- Std. 598 Valve inspection and test. **

- Std. 607 Fire test for soft seated quarter-turn valves.

ASME/ANSI-American National Standard

- B16.5 Steel pipe flanges and flanged fittings.

- B16.10 Face-to-face and end-to-end dimensions of ferrous valves.

- B16.34 Steel valves- Flanged and butt-welding ends.

EC-European Community

- CE Marked (P.E.D. 97/23/EC, Cat. 3) **

ISO-International Org. for Standardization

- ISO 9001 Quality systems-Model for quality assurance 2000 in design/development, production, installation and servicing.

- ISO 15156 Materials for use in H2S containing environments in oil and gas production.

MSS-Manufacturers Standardization Society

- SP 6 Standard finishes for contact faces of pipe flanges and connecting- end flanges of valves and fittings.

- SP 25 Standard marking system for valves, fittings, flanges and unions.

- SP 44 Steel pipeline flanges.

- SP 55 Quality standard for steel castings visual method.

NACE-National Assoc. of Corrosion Engineers

- MR0175 Sulfide stress cracking resistant metallic materials for oilfield equipment. (Superseded by ISO 15156)

**P.O.A. consult factory.

Order Matrix

View MatrixBill of Materials

View BillApplicable Design Standards

API American Petroleum Institute

6D Specification for Pipeline Valves

598 Valve Inspection and Test

607 Fire test for Soft Seated Quarter Turn Valves

608 Metal Ball Valves

ASME American Society of Mechanic Engineers

B16.5 Steel Pipe Flanges and Flanged Fittings

B16.10 Face to Face and End to End Dimensions of Ferrous Valves

B16.34 Steel Valves—Flanged and Butt Welding Ends

N31.4 Liquid Petroleum Transportation Piping Systems

B31.8 Gas Transmission and Distribution Piping Systems

ISO International Organization for Standardization

ISO 9001-2000 Quality Systems for Design/Development, Production, Installation, Servicing

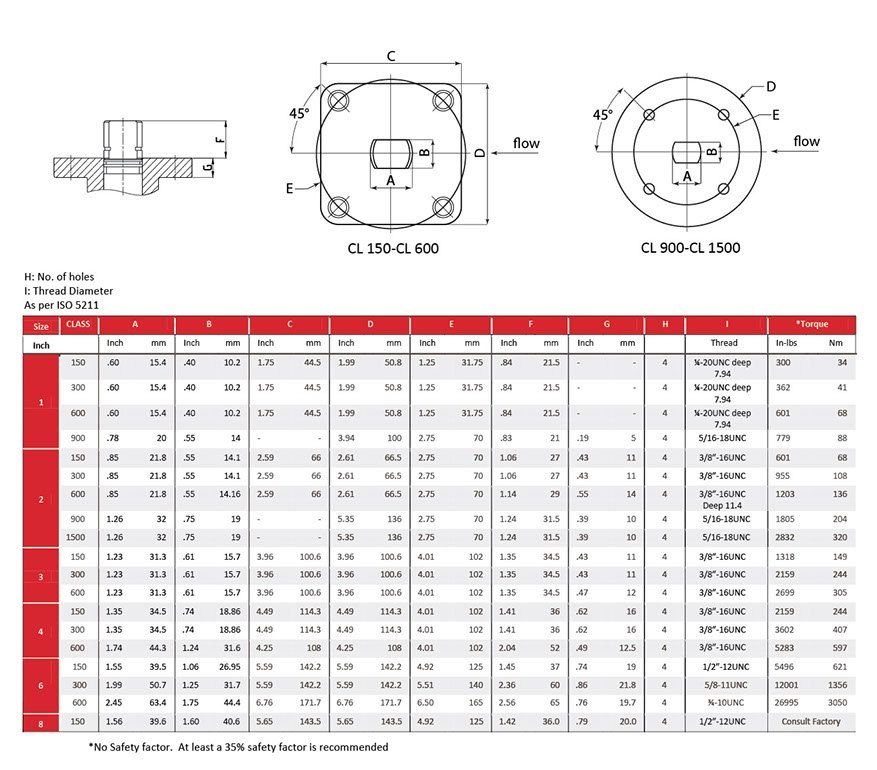

ISO 5211 Topworks for Mounting Dimensions

BS British Standard

BS 5351 Steel Ball Valves for the Petroleum, Petrochemical, and Allied Industries

MSS Manufacturers Standardization Society

SP 25 Standard Marking System for Valves, Fittings, Flanges and Unions

SP 45 Bypass and Drain Connection Standard

NACE National Association of Corrosion Engineers

MR0175 Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment

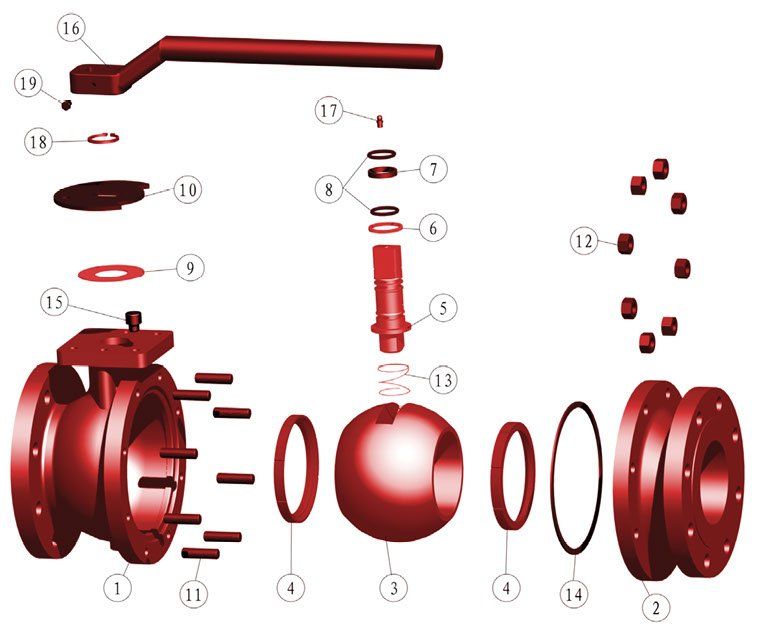

Component Parts

View Component DetailsDimensional Data (in.,mm)

Dimensional Data of 150/300

View DimensionsDimensional Data of 600

View DimensionsDimensional Data of 900

View DimensionsDimensional Data of 1500

View DimensionsTopworks & Stem Torque

Product Line Information

Trunnion Mounted Ball Valves

© 2024

Copyright | Tiger Valve Company