API-6A Gate Valves

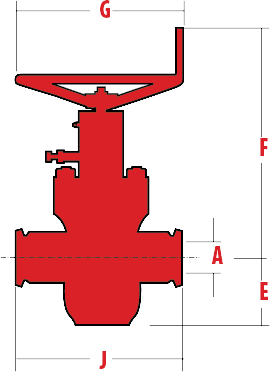

API-6A Hydraulic Gate Valves

We design our API-6A TVC Hydraulic Gate Valves to be Pipeline/Wellhead valves you can trust. These API 6A gate valves meet all of the industry standards for quality and safety. We have the full line of replacement parts available for our API-6A TVC Gate Valves, and we are determined to meet the needs of our customers for dependability and availability.

Take a look at TVC’s hydraulic gate valves order matrix below, and contact us

with any questions. Our hydraulic gate valve manufacturing experts are ready to help you find the valve that best suits your requirements. Whether you’re looking to distribute valves or utilize them at your facility, we have what you need at Tiger Valve.

TVC API-6A Gate Valves Order Matrix

View MatrixAPI Material Requirements

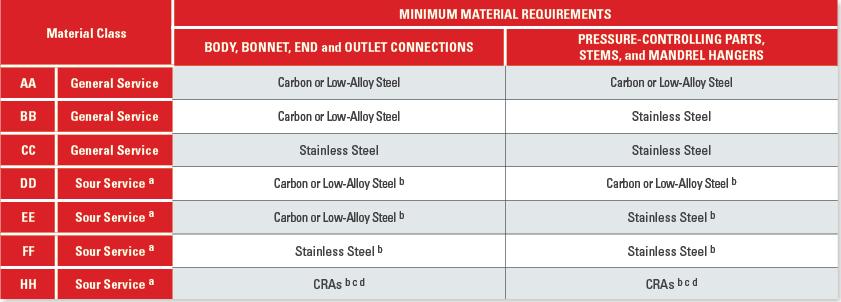

a

As defined by ISO 15156 (all parts) (NACE MR0175: see Clause 2).

b

In accordance with ISO 15156 (all parts) (NACE MR0175: see Clause 2).

c

CRA required on retained fluid-wetted surfaces only: CRA cladding of low-alloy or stainless steel is permitted [see 6.5.1.2.2 a].

d

CRA as defined in Clause 3: ISO 15156 (all parts) (NACE MR0175: see Clause 2) definition of CRA does not apply.

API-6A Product Specification Levels

Trim Chart: 2,000 – 5,000 PSI Expanding Gate Valves

View Chart

1. Nitriding is standard on all gates and seats. Tungsten Carbide, HF6 or other hardfacing techniques are also available.

2. Corrosion resistant alloy per NACE MR0175/ISO 15156.

3. High temperature (API Temp Ratings X,Y) valves use graphite packing. Other special packing is available upon request.

4. Teflon inserts on seat faces are standard in TVC valves. Metal-to-metal seats are available upon request.

5. Charpy impact test results are provided as required by API according to the temperature rating and material class.

6. Materials for sour service trims conform to latest edition of NACE MR0175. Explanation for suffixes used for sour trims:

0.5 = 0.5 psi maximum partial pressure of hydrogen sulfide

1.5 = 1.5 psi maximum partial pressure of hydrogen sulfide

NL = No limit to hydrogen sulfide exposure.

7. TVC reserves the right to use material class ZZ when customers request materials of construction that do not comply with current NACE MR0175/ISO standards.

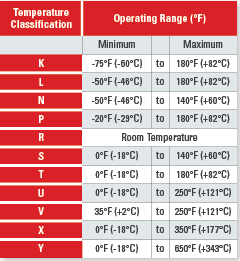

Temperature Ratings

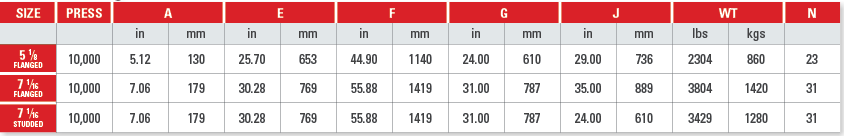

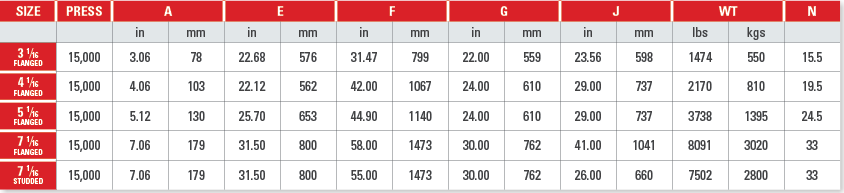

Trim Chart: 10,000 – 15,000 PSI SLAB Gate Valves

View Chart

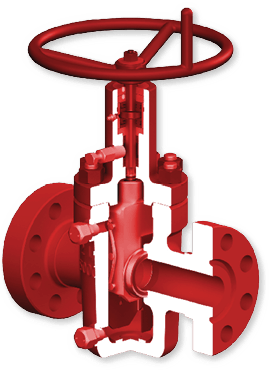

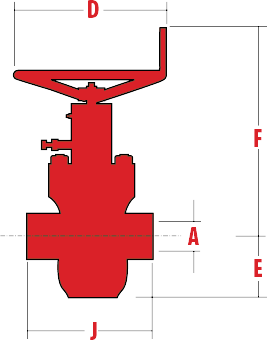

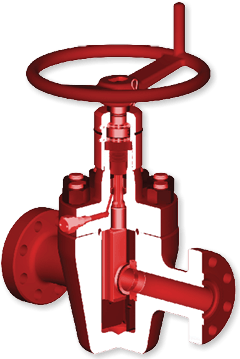

Model TMX Gate Valves

TVC Model TMX cast-body expanding gate valves are designed for oil and natural gas wellhead or other critical service applications with operating pressures from 2,000 to 5,000 psi. All Model TMX expanding gate valves are API 6A Latest Edition monogrammed equipment and are available in bore sizes ranging from 2-1/16" through 7-1/16".

Operating Temperatures

Model TMX valves are available with API 6A Temperature ratings of L (-50 F) through Y (650 F). Valves for API Temperature ratings of X and Y are pressure de-rated as required per Annex G of API 6A Latest Edition.

Expanding Gate

The expanding gate is field-replaceable and provides a tight mechanical seal that does not rely on line pressure. This ensures seal integrity at both high and low pressures.

Seat Designs

The standard gate to seat and seat to body sealing interface is a slip-fit design, assisted by inserts in the face and rear of each seat. Metal-to-metal gate to seat and pressed-fit seat to body sealing is used for high-temp valves and is otherwise available upon request.

Packing Design

Chevron style stem packing is replaceable and can be re-energized by injection between the packing stacks. This ensures efficient sealing for the life of the valve. Graphite packing is used for high-temperature applications.

Body Lubricant

All Model TMX valves are shipped with body filler grease appropriate for the material class and temperature rating of the valve to ensure smooth operation of the valve under pressure and to prevent corrosion during storage prior to deployment.

Grease Fittings

The valve body may be lubricated through the grease fittings provided in the valve body. All fittings meet the requirements of NACE MR0175.

Exposed Bolting

All exposed bolting meets the requirements of NACE MR0175.

Full Through Conduit Bore

The full through conduit bore provides for smooth flow with minimal turbulence. It also provides an unobstructed passage for well intervention tools.

All Model TMX valves are drift tested in accordance with API 6A Latest Edition requirements.

Model TMX 2,000 – 5,000 PSIExpanding Gate Valves

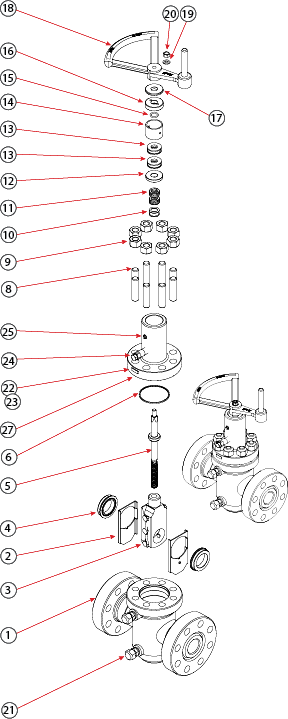

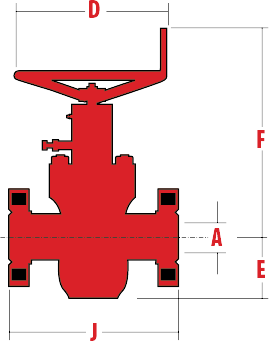

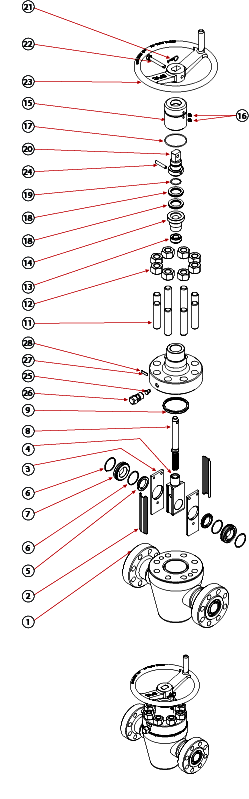

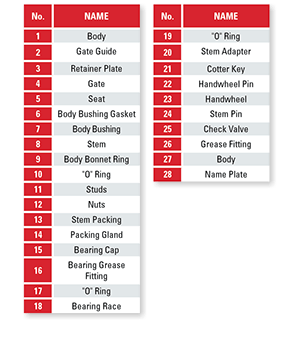

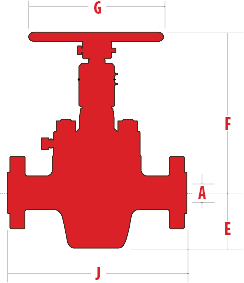

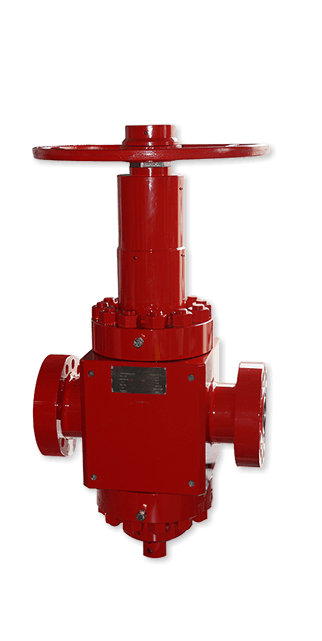

Model TFC Gate Valves

TVC Model TFC forged-body slab gate valves are designed for oil and natural gas wellhead, manifold or other critical service applications with operating pressures from 10,000 to 15,000 psi. All model TFC slab gate valves are API 6A Latest Edition monogrammed equipment and are available in bore sizes ranging from 1-13/16" through 5-1/8".

Operating Temperatures

Model TFC valves are available with API 6A Temperature ratings of L (-50 F) through Y (650 F). Valves for API Temperature ratings of X and Y are pressure de-rated as required per Annex G of API 6A Latest Edition.

Slab Gate

The single piece slab gate is field-replaceable and provides the valve with full bi-directional sealing capability at both high and low pressures.

Seat Design

The standard gate to seat and seat to body sealing interface is a two-piece design consisting of a seat ring and a body bushing, assisted by inserts in the rear of each piece. Metal-to-metal gate to seat interface is standard. Metal inserts are used for high-temperature applications.

Packing Design

Stem packing is replaceable and assisted by an anti-extrusion ring. This ensures efficient sealing for the life of the valve. Graphite packing is used for high-temperature applications.

Integrated Backseat

All Model TFC valves have an integrated metal-to-metal stem to bonnet backseat. When valve is in backseat position, pressure is contained within the valve cavity and cannot ingress into bonnet or stem packing area.

Grease Fittings

The valve body may be lubricated through the grease fitting provided in the valve bonnet. An in-line check valve is provided behind the grease fitting to ensure a unidirectional flow. All fittings meet the requirements of NACE MR0175.

Lubrication and Corrosion Protection

All Model TFC valves have body cavity lubrication appropriate for the material class and temperature rating of the valve. This ensures smooth operation of the valve under pressure and prevents corrosion during storage.

Full Through Conduit Bore

The full through conduit bore provides for smooth flow with minimal turbulence. It also provides an unobstructed passage for well intervention tools.

All Model TFC valves are drift tested in TM with API 6A Latest Edition requirements.

Model TFC 10,000 – 15,000 PSISlab Gate Valves

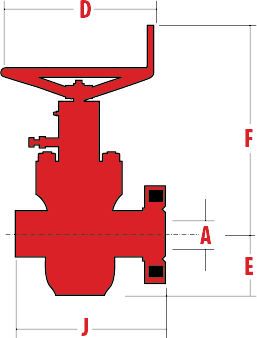

Model TBS 10,000 – 15,000 PSISlab Gate Valves for Frac Service

TVC Model TBS (Ball-Screw Operated) forged body slab gate valves are designed for High-Pressure / Large-Bore applications which are exposed to abrasive and high fluid volumes such as Fracking Operations or other critical service requirements with working pressures from 10,000psi thru 20,000psi. All Model TBS slab gate valves are API 6A Latest Edition Monogrammed and are available in bore sizes from 4 1/16" thru 7 1/16" with features as follows:

- Frac valve service

- Bi-directional flow and seal capabilities

- Metal to Metal sealing (gate to seat–seat to body–backseat fire safe seal)

- Non-rising stem design

- Forged body and bonnet

- Low operating torque

- No special tools required for repairs

- Full bore design

- Fewer turns manually for open-close cycles

- Manual ball screw or hydraulically actuated

Model TBS 10,000 – 15,000 PSISlab Gate Valves for Frac Service

Product Line Information

Trunnion Mounted Ball Valves

© 2024

Copyright | Tiger Valve Company