Rack and Pinion Actuators

Rack and Pinion Actuator

Below, you’ll learn about the various components of Tiger Valve state-of-the-art rack and pinion actuators. We also cover the operating conditions and mounting standards that our expert rack and pinion actuator manufacturers recommend.

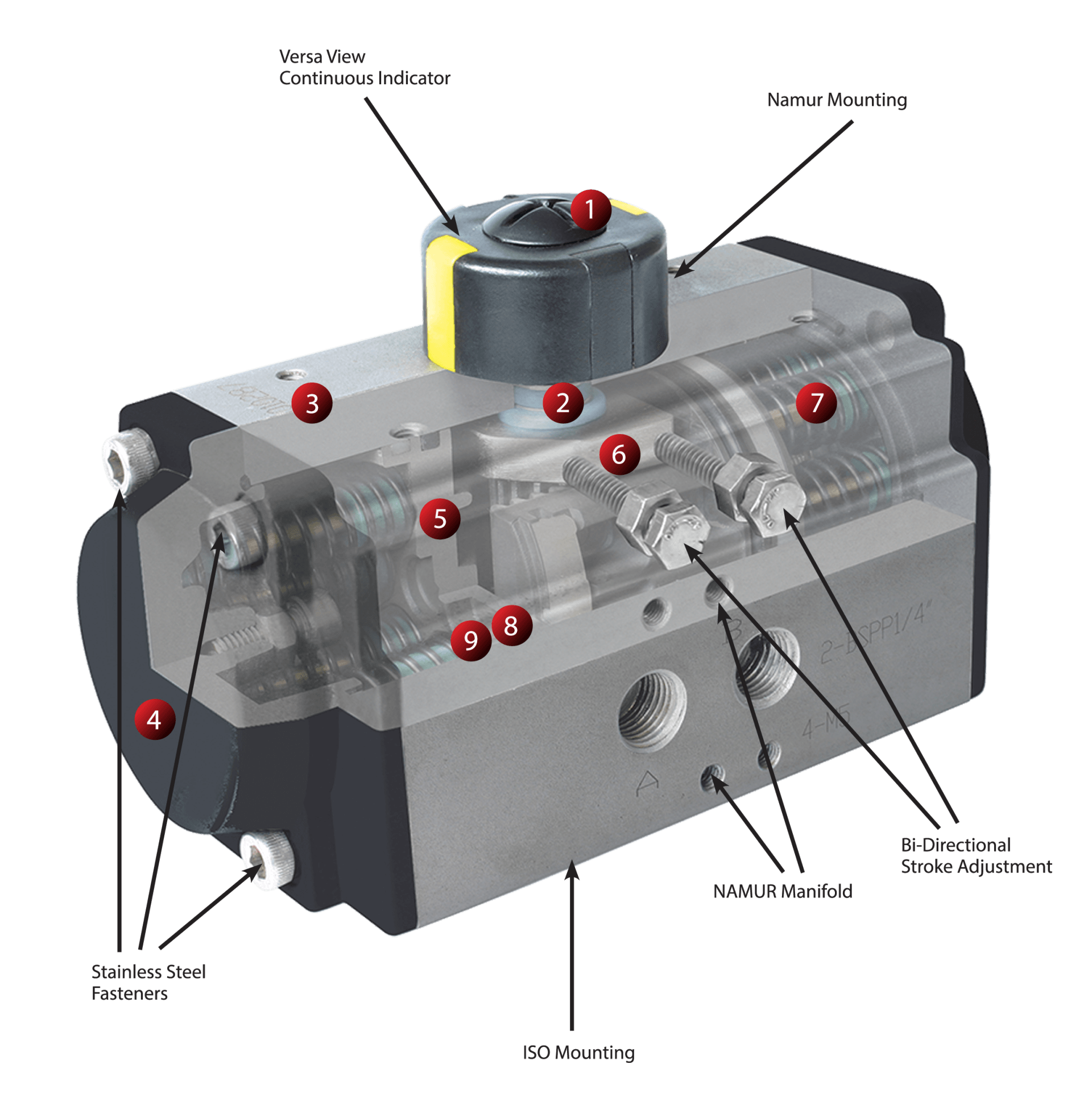

Construction

Pistons

The twin rack pistons are made from die cast aluminum then hard anodized. Also available from cast steel and galvanized. The pistons are symmetrically positioned for long cycle life and fast operation. Reversing rotation is simply performed by inverting the pistons.

Travel Adjustment

The two independent external travel stop adjustment bolts can adjust ±5° at both open and close directions easily and precisely.

High-Performance Springs

Preloaded coated springs are made from high-quality material resistant to corrosion and longer service life, which can be changed safely and conveniently to satisfy different requirements of torque by changing the quantity of springs.

Bearings & Guides

Made from low friction, long-life engineered plastics, to avoid direct contact between metals. Maintenance and replacement are easy and convenient.

Operating Conditions

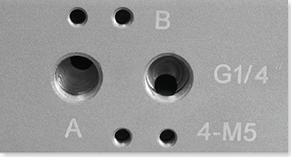

1. Operating media

Dry or lubricated air, or non-corrosive gases

2. Air supply pressure

The minimum supply pressure is 45 psi

The maximum supply pressure is 116.0 psi

3. Operating temperature

Standard: -4°F ~ +175°F

Low temperature: -35°F ~ +175°F

High temperature: +5°F ~ +302°F

4. Travel adjustment

Adjustment range of ±5° for the rotation at 0° and 90°

Mounting Standards

Model Comparison

View SpecsParts and Materials

View Parts and Materials ChartPrinciples of Operation

Double Acting Actuators

Spring Return Actuators

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise

while air is being exhausted from port B.

Loss of air pressure on port A causes the stored energy in the springs to force the pistons inwards. The pinion turns clockwise

while air is being exhausted from port A.

Air to Port A forces the pistons outwards, causing the pinion to turn clockwise

while the air is being exhausted from Port B.

Loss of air pressure on port A causes the stored energy in the springs to force the pistons inwards. The pinion turns counterclockwise

while air is being exhausted from port A.

Output Torque Double Acting Actuators

View SpecsSizing: Double Acting Actuators

The suggested safety factor for double acting actuators under normal working conditions is 20%-30%.

Output Torque of Spring Return Actuators

View SpecsDimensional Data

View SpecsSizing: Spring Return Actuators

The suggested safety factor for spring return actuator under normal working conditions is 30-50%

Example:

The torque needed by the valve=700 in. Lbs.

The torque plus a safety factor ( 700 in. Lbs. + 30% = 910 in. Lbs. ) Air Supply = 80 psi

According to the table of spring return actuators’ output, we find output torque of TR125SRK10 (Fail CW)

Spring Mounting Form for Spring Return Actuators

During the selection of spring return actuators, we can choose the more reasonable and more economical actuators, if we konw the different torque needed by the valve working at 0°, 45° and 90°.

NOTE:

Make certain the torque necessary to operate the valve is compatible with the actuator torque. Note that the requested torque depends not only on the valve,but on the working conditions and the safety margins of the valve and actuator

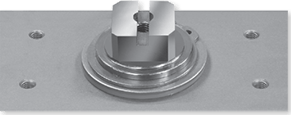

Actuator Inserts

View Specs120°, 135°, 180° Double Acting and Spring Return

In order to meet the special requirements of control valve we produced special strokes actuators on costumer request (e.g. 120°,135°,180°etc.).

Output Torque—

Output torque of double acting actuators please refer to the torque of 90°actuators.

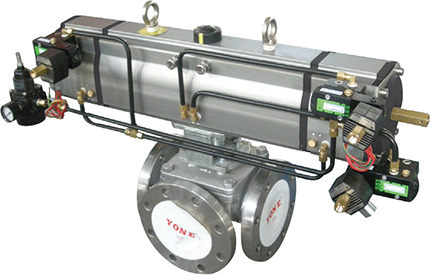

Three Position Pneumatic Actuator

Three position actuator provide an operation of 0°, 45°, 90°or 0°, 90° and 180°. The midway position is achieved by a mechanical stop of movement on the two auxiliary pistons. The midway stop positions are adjustable. Example: 90° actuator can provide 20°, 30°, 40°, 50°, 70° etc.

Output Torque—

Output torque of double acting actuators please refer to the torque of 90°actuators.

Schematic Diagrams

Contact us

with any questions you have about our rack and pinion actuators. As a rack and pinion actuator manufacturer, we’re committed to providing you with reliable and efficient products for use or distribution.